What is the Vertical Shaft Impact Crusher? Vertical Shaft Impact Crusher is what properties of the crushing equipment?

Vertical Shaft Impact Crusher is a new product that absorbs advanced technologies at home and abroad. This Series equipment can crusher material which max feed size is less than 500mm, compression strength is not more than 320 Mpa (eg: granite, limestone, concrete etc.) With its excellent performance and good performance, Impact Crusher is widely used in highway, hydroelectric, artificial stone and sand, crushing and building material industry ect.

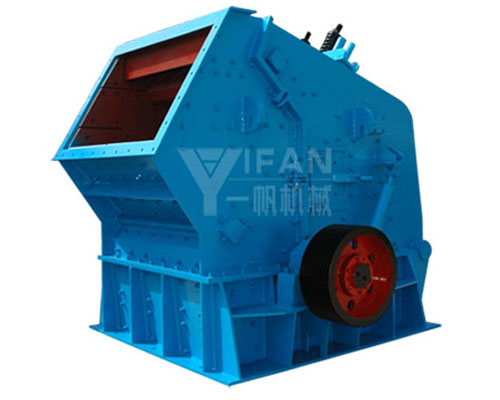

Vertical Shaft Impact Crusher is a kind of mining machinery industry commonly used hard stone crushing equipment, referred to as the counterattack break, impact crusher is suitable for crushing hard material, because of the simple structure, power consumption saving, broken ratio, product size uniform advantages, in metallurgy, coking, chemical, building materials, refractory materials and other industrial sectors widely used, such as cement limestone crusher, has a large capacity, a small particle size advantages

|

| impact crusher |

Vertical Shaft Impact Crusher technical characteristics :

[1] .Multiple cavity is crushed, suitable for crushing hard rock, high efficiency and energy saving.

[2] .Low and big feed port, convenient production line layout and increase the size of feeding material.

[3] .Full hydraulic open, easy to repair and replacement of wearing parts, product shape of a cube, nesting adjustable particle size, simplified crushing process.

[4] .The unique tooth type counterattack scaleboard, new wear-resistant materials so that the plate hammer, back lining and lining board with longer life.

Vertical Shaft Impact Crusher classification:

Vertical Shaft Impact Crusher according to their structural characteristics can be divided into the single rotor impact crusher ( back broken) and double rotor impact crusher ( back broken). Rotor turning, single rotor impact crusher the reversible rotary and not reversible turn two big types. Double rotor impact crusher can be classified to rotate in the same direction, reverse rotation type and the opposite direction rotation type three types. According to the internal structure, single rotor impact crusher is divided again with even grate plate and without regularity grate plate two forms. Double rotor impact crusher can be divided into the rotor at the same level and the rotor is not at the same level in two forms.

Vertical Shaft Impact Crusher has such advantages as: simple in structure, large crushing ratio, low energy consumption, high output, light weight, cubic final product, and it is usde in mineral processing, chemical, cement, construction, refractory material, ceramics, glass, etc, such industrial sector for midium, fine and medium-hard materials. Eg: limestone, clinker, slag, carbon coke, coal etc. Vertical Shaft Impact Crusher has larger crushing ratio, and can make full use of the high-speed impacting energy of the entire rotor. However, due to the blow bar is easily to wear, so it is restricted in hard materials. So Impact Crusher is mainly usde in coarse, midium, and fine crush, such as, limestone, coal, Calcium Carbide, quartz, dolomite, sulfuration iron ore, gypsum, chemical raw material etc, under midium hard brittle material. the ideal size of Vertical Shaft Impact Crusher is from 100-500mm, the max feed size shouldn't exceed the specified value. Users can adjust the space between the hammer and Impact plate, components of the machine, then get the final product.

[2] .Low and big feed port, convenient production line layout and increase the size of feeding material.

[3] .Full hydraulic open, easy to repair and replacement of wearing parts, product shape of a cube, nesting adjustable particle size, simplified crushing process.

[4] .The unique tooth type counterattack scaleboard, new wear-resistant materials so that the plate hammer, back lining and lining board with longer life.

Vertical Shaft Impact Crusher classification:

Vertical Shaft Impact Crusher according to their structural characteristics can be divided into the single rotor impact crusher ( back broken) and double rotor impact crusher ( back broken). Rotor turning, single rotor impact crusher the reversible rotary and not reversible turn two big types. Double rotor impact crusher can be classified to rotate in the same direction, reverse rotation type and the opposite direction rotation type three types. According to the internal structure, single rotor impact crusher is divided again with even grate plate and without regularity grate plate two forms. Double rotor impact crusher can be divided into the rotor at the same level and the rotor is not at the same level in two forms.

Vertical Shaft Impact Crusher has such advantages as: simple in structure, large crushing ratio, low energy consumption, high output, light weight, cubic final product, and it is usde in mineral processing, chemical, cement, construction, refractory material, ceramics, glass, etc, such industrial sector for midium, fine and medium-hard materials. Eg: limestone, clinker, slag, carbon coke, coal etc. Vertical Shaft Impact Crusher has larger crushing ratio, and can make full use of the high-speed impacting energy of the entire rotor. However, due to the blow bar is easily to wear, so it is restricted in hard materials. So Impact Crusher is mainly usde in coarse, midium, and fine crush, such as, limestone, coal, Calcium Carbide, quartz, dolomite, sulfuration iron ore, gypsum, chemical raw material etc, under midium hard brittle material. the ideal size of Vertical Shaft Impact Crusher is from 100-500mm, the max feed size shouldn't exceed the specified value. Users can adjust the space between the hammer and Impact plate, components of the machine, then get the final product.

Vertical Shaft Impact Crusher Features and Benefits:

[1]、Many cavity to crush, suitable for crushing hard rock.

[2]、Low and big feed opening make the production line easy to arrange and increase the size of feeding material.

[3]、New anti-abrasive material which prolong service life of impact hammer, impact plate and liner.

[4]、High-chromium plate hammer, unique Impact plate, especially for hard rock crushing, high efficiency and energy saving.

[5]、Hard stone crushing, high efficiency and energy saving.

[6]、Reasonable design of leveling plate making the finished material finer and cubic-shaped without internal cracks.

[7]、the shape of the products are cube, the discharge opening size can be adjusted.

[8]、Simplify the Crushing process.

[9]、Hydraulic start-up which is convenient for maintenance and replacement of wear-parts.

No comments:

Post a Comment